Semi-Auto Heat Transfer Screen Printing Kab

SCREEN PRINTING TSHUAB

Cov ntawv ntxiv

1.1 Daim Ntawv Thov Ntau Yam:

Lub tshuab ZSA-1B yog tsim rau kev luam ntawv ntawm cov ntawv, PCB, yas, hlau, iav thiab cov khoom tsim.

1.2.Nta:

1.2.1 Stainless hlau worktable, pem hauv ntej-rov qab thiab txoj cai-sab laug inching kho, thiab txheej txheem luam ntawv sai thiab yooj yim.

1.2.2 Peb txoj kev tswj tau xaiv tau: phau ntawv, ib leeg, tsis siv neeg

1.2.3 Txhawm rau kom phim nrog ntau yam ntawm tus cwj mem thiab tau txais cov txiaj ntsig luam ntawv sib txawv, cov scraper thiab number case reclaiming daim ntawv tuaj yeem tswj tau kom nres ntawm sab xis lossis sab laug.

1.2.4 Txais cov khoom siv hluav taws xob zoo heev ua los ntawm cov tuam txhab nto moo, lub cev muaj zog thiab PLC.High precision grinded linear phau ntawv qhia kev ua haujlwm du thiab dura billity ntawm lub tshuab.

2. Cov lus qhia tshwj xeeb

| 1 | Qauv | XH-6090 |

| 2 | Max Printing Area | 600 x 900 mm |

| 3 | Worktable Dimension | 700 x 1000 mm |

| 4 | Max.Screen Ncej | 1380 x 1100 mm |

| 5 | Thickness | 0-20 hli |

| 6 | Max.Printing ceev | 13 / min |

| 7 | Cua siab | 3HP, 5.5-7.7kg/cm2 |

| 8 | Fais fab mov | 380V, 2 KW |

| 8 | Zuag qhia tag nrho | 1600mm * 1060mm * 1680mm |

| 9 | Qhov hnyav | 580kg (kwv yees) |

| 10 | Case Xim | Dawb / Xiav |

Peb tuaj yeem kho lwm qhov loj me rau cov neeg siv.Customized loj thiab hnyav pls ua raws li cov khoom siv tiag tiag.

3. Cov lus piav qhia txog kev ua haujlwm

- Lub zog ntsuas

- Barometer rau luam ntawv squeegee

- Printing Speed regulating knob

- Cov roj rov qab ceev regulating pob qhov rooj

- Kev luam ntawv suav

- Thib ob luam ntawv

- Hom kev ua haujlwm

- Nws pib lub sij hawm tso saib

- Tsis siv neeg lub sijhawm

- Ascending nqis

- Roj rov qab

- Scraping conversion

- Cua nqus hom

- Roj rov qab sai

- Kev luam ntawv

- ON/Off Rauv

- Scraper Siab

- Kev nyab xeeb valve

- Lub taub hau luam ntawv

4. Kev teeb tsa thiab kuaj

4.1 Lub tshuab yuav tsum tau nruab rau hauv ib puag ncig ntawm qhov tseeb, thiab qhov kub thiab txias nyob rau hauv 18-28 degree.

4.2 Kos lub fastener zoo haum, thiab qhov txav tau muaj roj lubrication tom qab qhib lub thawv ntoo.Xaiv qhov chaw zoo rau lub tshuab, haum 4 roj hmab rau ob txhais ceg, kho nws thiab khaws lub rooj ua haujlwm nyob rau hauv kab rov tav.Hauv av hlau yuav tsum txuas nrog lub tshuab.

4.3 Ob chav xim hlau yog av xaim, lwm tus yog hluav taws xob hlau.Tom qab cov hlau txuas tau zoo.Nias 'Operation Mode' rau 'Manual'.

Nias 'Air Suction Mode' rau 'suction tas mus li'.

Qhib lub hwj chim (saib daim duab 1.4).Qhib 'Safety Valve' rau.

Qhov ntawd yuav ua rau tus kiv cua ua haujlwm.Muab ib daim ntawv nplaum nplaum rau ntawm lub rooj ua haujlwm, yog tias daim ntawv tau nqus los ntawm lub rooj ua haujlwm.Nws txhais tau hais tias cov xov hlau txuas yog raug.Yog tias daim ntawv raug cua tshuab, nws txhais tau hais tias lub zog hluav taws xob xaim rov qab rau hauv theem, thim rov qab ob ntawm hluav taws xob hlau.

4.4 Cov cua siab rau lub tshuab yog 5.5 ~ 7KG / cm2.Yog tias huab cua siab qis dua tus naj npawb, rub tawm lub adjustor, tig clockwise, ua rau huab cua siab.Tig counterclockwise yuav ua rau huab cua siab qis.

4.5 Nias 'Operation Mode' rau 'manual' tswj.Ntsuas lub tshuab nce thiab nqis, sab laug thiab txoj cai txav.

Nias 'Scraping conversion' khawm, sim cov scraper, thiab roj rov qab scraper.

Ceeb toom: Tsis tuaj yeem ua lwm yam haujlwm, kom txog thaum tag nrho cov saum toj no ua haujlwm zoo.Txwv tsis pub, yuav ua rau lub tshuab puas.

4.6 Ua tiav saum toj no, ua raws li Tsis Siv Neeg thiab Ib Leeg luam ntawv xeem.

4.6.1 Nias 'Operation mode' rau 'Single', kauj ruam ko taw pedal, ces tiav ib zaug luam ntawv.

4.6.2 Nias 'Rapid Oil Return button', Screen zaub

Lub zog yog:

Down-Scraper laug txav —-up, Scraper txoj cai txav

Yuav ua kom cov luam ntawv efficiency.

4.6.3 Nias 'Second printing' ON, lub zog yog:

Down-Scraper Left txav — Txoj cai —-Sab laug — Txoj cai — Up

Haum rau thicker number case printing.

4.6.4 Nias 'Operation mode' kom tsis siv neeg, kho Timer Control KT(0 ~ 10S).Lub tshuab ua tiav tag nrho cov txav tsis siv neeg.(Sitable rau cov neeg ua haujlwm txawj ntse, hloov Foot pedal)

4.6.5 Khawm Emergency

Khawm Emergency tuaj yeem nqa thaum lub tshuab ua haujlwm.Yuav tsum tau ua tus taw pedal kom lub tshuab khiav tom qab siv lub khawm Emergency.

5. Kev ua haujlwm piav qhia

5.1.Install and adjust Net Frame

Tig mus rau 'Muab Cua' (raws li daim duab 1.35), ua rau Scraper nce, xoob Net Frame Arm ntsia hlau (raws li daim duab 1.9).Kho lub Net Ncej caj npab nyob rau hauv ob sab kom haum ntev (raws li daim duab 2.25), nruab lub Net Ncej rau lub clamp ces kaw lub hau.(raws li duab 1.29).Ua tiav ntsia, kaw lub hau.(raws li duab 1.9)

5.2.Kho qhov luam ntawv loj.

Hloov lub tshuab luam ntawv scraper roj hmab los kho cov ntawv luam ntawv dav raws li koj qhov kev thov.(raws li duab 1.33).

Kho qhov ntev ntawm kev luam ntawv: xoob 2 screws (raws li daim duab 1.11), kho sab laug thiab sab xis kom haum qhov chaw.Tight lub hau.

Kev luam ntawv thiab Roj rov qab nrawm kho (raws li daim duab 3) 'Printing Speed', rau koj qhov nrawm nrawm.

5.3.Ua raws li hauv qab no kom kho cov scraper thiab rov qab roj riam.

ib.Kev sib hloov: tso 4 lub taub hau (raws li daim duab 1.24) los kho qhov kev sib hloov.

b.Parallelism: kho 4 screws (raws li daim duab 1.12) kom cov scraper thiab rov qab roj riam ua ke nrog Net Ncej nto.

c.Ceev: Kho 4 ntsia hlau (raws li daim duab 1.12) ntawm sab xis los tswj lub nqa ceev ntawm Scraper thiab roj rov qab riam.Kho 'printing ceev' los tswj qhov ceev ntawm scraper.

d.Siab rau scraper: Kho lub siab valve (raws li daim duab 1.39) los tswj lub siab ntawm scraper (raws li daim duab 1.38).Nyeem tus lej los ntawm Barometer.

e.Rub lub pob qhov rooj 'lub taub hau luam ntawv' tawm (raws li daim duab 3.19), kom tshem tawm cov scraper thiab roj rov qab riam.Nruab lub scraper thiab roj rov qab riam nias lub 'lub taub hau luam ntawv'.

5.4.Kho qhov siab ntawm Net Frame thiab worktable.(Raws li lub thickness ntawm workpiece) Tom qab lub tshuab, qhib lub qhov rooj.

Loos lub hau.(saib daim duab hauv qab no) Tig tus pas nrig rau kev tiv thaiv clockwise kom nce, tig tus pas nrig rau clockwise kev coj mus rau hauv.

Tight lub hau.

| TSIS MUAJ. | Lub npe | TSIS MUAJ. | Lub npe |

| 1 | Adapter rau pedal hloov | 22 | Cua Drum rau scraper |

| 2 | Universal log | 23 | Ink Riam Lock Screw |

| 3 | Lub zog nkag | 24 | Ink Riam Rotative adjustor |

| 4 | Hloov fais fab | 25 | Arm ntawm Net Frame |

| 5 | Micro adjustor rau Worktable | 26 | Pillar rau Lift Net Ncej |

| 6 | Worktable Lock Screw | 27 | Ceev Adjustor rau Lift Net Ncej |

| 7 | Net Ncej Rotative Adjustor | 28 | Lift Net Frame Air Drum |

| 8 | Net Ncej Qhov siab Kho Screw | 29 | Screw rau Tighten Net Ncej |

| 9 | Net Ncej Sab laug & Txoj Cai Kho Screw | 30 | Sab laug & Txoj Cai Net Ncej |

| 10 | Tsav | 31 | Lub rooj ua haujlwm |

| 11 | Movement locker | 32 | Hook for Ink Riam |

| 12 | Scraper Speed Adjuster | 33 | Scraper |

| 13 | 34 | Ink riam | |

| 14 | Cua Drum rau scraper | 35 | Cua Drum rau scraper |

| 15 | 36 | Nres Thaum Muaj Xwm Ceev | |

| 16 | Drag Chain | 37 | Vaj huam sib luag |

| 17 | 38 | Scraper Barometer | |

| 18 | Sab Nraud | 39 | Scraper Siab Adjustor |

| 19 | 40 | Hluav taws xob qhov rooj qhov rooj | |

| 20 | Ink Return Riam Siab Adjustor | 41 | Ko Taw Pedal |

| 21 | Scraper Siab Adjustor |

6. Kev tu:

6.1.Tsis txhob muab tus cwj mem thiab cov kuab tshuaj organic thaiv lub qhov nqus ntawm lub rooj ua haujlwm.

6.2.Tso me ntsis roj cav 10 # ntawm tus ncej txhua qhov ua haujlwm ua haujlwm.

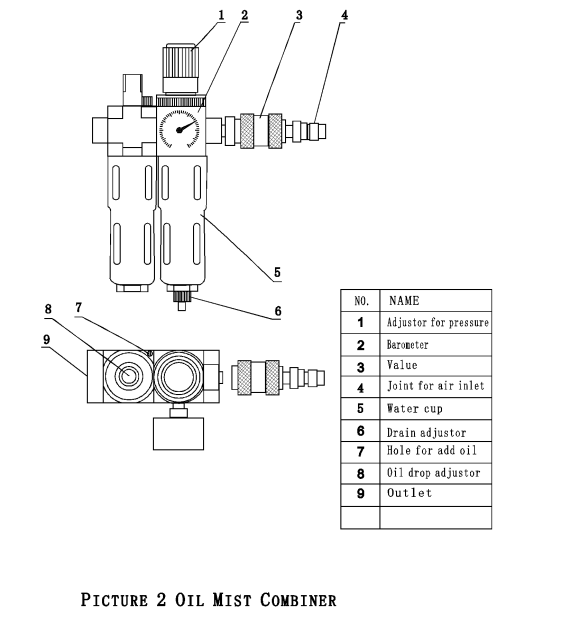

6.3.Lub tshuab muaj roj pos huab ua ke (saib daim duab 2).

6.4.Ntxuav lub Lim (raws li daim duab 2.7).Muab cov cua, tig lub qhov dej ntws (raws li daim duab 2.8).

Ntxuav daim txhuam cev hauv lub khob dej (raws li daim duab 2.7) zaus.Tshem lub Lim tawm, tshem tawm daim txhuam cev, tawm ob peb feeb hauv dej ntshiab, thiab qhuav nws.

7. Daim ntawv txuas

1. Phau ntawv ua haujlwm

2. Screwdriver 2 pcs, 10 'Spanner, hex Spanner, Rob

3. 4 Roj hmab ko taw

4. Scraper thiab Ink rov riam 350, 400

******************************************************** ******************************************************** ******************************************************** *********************

POWDER COATING TSHUAB

Cov lus piav qhia luv luv

Cov khoom siv tom qab luam ntawv corollary uas hloov cov khoom siv tes ua haujlwm.Lub tshuab no yooj yim rau kev thov, ua haujlwm zoo, yoog raws, thiab tsis muaj kev sib kis, uas ua rau kom muaj txiaj ntsig zoo thiab siv cov khoom siv raw, nrog rau tsim cov duab zoo nkauj.

Nyob rau hauv lub tshuab no, qhov chaw rau txoj hauj lwm tseem ceeb xws li hmoov nqus, transducer yog imported nrog qhov zoo ntawm kev ruaj khov thiab ruaj khov.Tshwj xeeb tshaj yog, lub tshuab no ua haujlwm zoo nrog cov uas xav tau siab ntawm daim ntawv, zaj duab xis, glitter, thiab cov hmoov kub melting.Tag nrho cov tsav tsheb nyob rau hauv lub tshuab no yog infinite ceev variation.Yog tias xav tau, nws tuaj yeem txuas nrog cov cuab yeej ziab khaub ncaws thiab cov khoom siv kho mob UV.

Main Technical Parameters:

| Qauv | Tag Nrho Lub Zog | Dav ntawm Transmission Belt | Dav ntawm Powder | Thickness ntawm ntawv | Zuag qhia tag nrho Dimensions | Ceev (Pcs / teev) |

| ZSCT-II | 4.5 KW TSI | 1000 (mm) | 900 (mm) | 1-5 (mm) | 2000 * 1700 * 2000 hli | 2000 |

Nyeem phau ntawv kom zoo, ua ntej ua haujlwm lub tshuab.Tsis txhob kho ib qho ntawm lub pob ua ntej txuas rau hluav taws xob fais fab.

Phau ntawv ua haujlwm

Warmly ceeb toom: Cov hmoov yuav tsis tawg mus txog thaum zaj duab xis dhau muslub sensor.

Lub tshuab no tau nruab nrog cov keyboards sib cais rau ob qho tib si lub zog nqus dej nce thiab nqis, nrog rau cov keyboards rau kev xa tawm, plua plav, hmoov pub mis, thiab electrostatic neutralizer.

Cov txheej txheem pib

- Hloov lub zog tseem ceeb ntawm rooj plaub sab laug.

- Qhib lub hwj chim hloov (Saib daim duab II-2).

- Hloov mus rau lub zog nqus lub cev muaj zog (Saib daim duab II-8), thiab ua kom pom tseeb qhov zaus ntawm transducer mus rau 38-42HZ .

- Hloov mus rau downward zog nqus lub cev muaj zog (Saib daim duab II-11), thiab ua kom pom tseeb qhov zaus ntawm transducer rau 55-65HZ.

- Hloov ntawm lub zog xa khoom (Saib daim duab II-4), thiab hloov mus rau 20-65HZ.

- Hloov ntawm cov hmoov pub noj adjustor (Saib daim duab II-15), thiab hloov mus rau 20-65HZ.

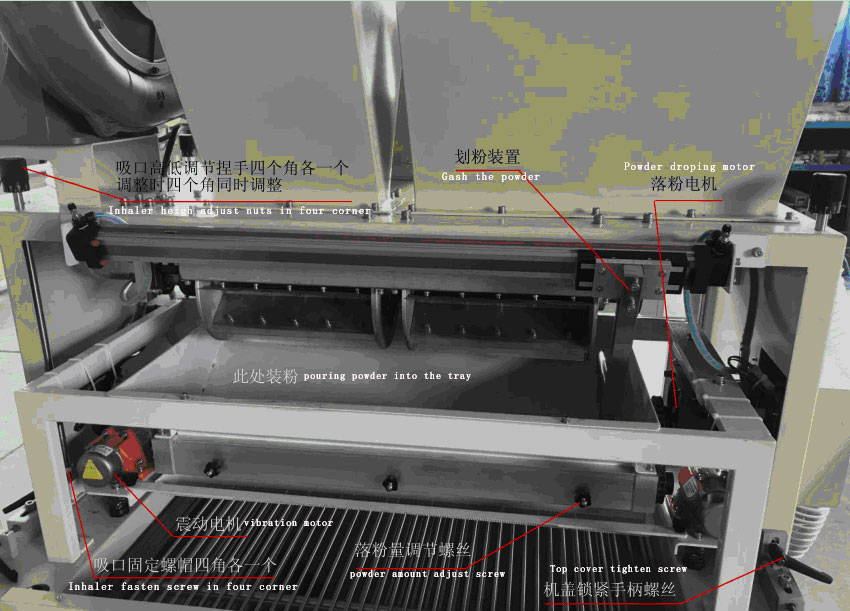

- Ncuav cov hmoov kub yaj rau hauv lub tais plua plav, thiab tom qab ntawd hloov lub tshuab nqus plua plav (Saib daim duab II-17).Ua ntej, kho qhov ceev ntawm plua plav (qhov nrawm dua, cov hmoov ntau dua).Los yog kho peb lub txiv ntseej nyob rau hauv lub plua plav funnel (Saib daim duab I-4) kom pom tseeb tus nqi ntawm cov hmoov, kom ua tau raws li cov khoom xav tau rau cov hmoov tuab thiab sib npaug.

- Powder collector ntawm sab laug rooj plaub (Saib daim duab II-21) muaj nuj nqi ntawm kev txhawb nqa hmoov-cycling.Feem ntau, nws yog hloov ntau ntawm 60 mus rau 70.

- Qhib qhov hloov hluav taws xob electrostatic neutralizer (Saib daim duab II-13)

Kho tshuab

1.Kho qhov chaw nruab nrab ntawm cov hmoov nqus dej nce thiab nqis mus rau 2-3 hli.

Yog tias tseem muaj lub iav log ntawm tus qauv thaum ua haujlwm (feem ntau, nws twb tau hloov kho ua ntej rollout), koj tuaj yeem kho qhov siab rau lub zog nqus dej kom tau raws li cov khoom xav tau.

1.1 Tso plaub lub txiv ntoo ntawm lub ces kaum.Lus Ceeb Toom: Kho qhov siab tsuas yog tom qab tso plaub lub txiv ntoo.(Saib daim duab)

1.2 Tso cov txiv ntoo (Saib daim duab 1), kho qhov siab kom haum rau lub zog nqus (Saib 1, 21, 22).Lossis (Saib daim duab 1) Tig lub voj voog kom ze rau qhov sib txawv.Tig anticlockwise qhov sib txawv tau dav.

1.3 Fine-tig plaub txiv ntseej ntawm hmoov nqus, ua kom sib npaug.(Saib daim duab 1) Tighten cov ntsia hlau dub (Saib daim duab 1)

Hmoov txheej txheej txheem

1.Yog tias muaj cov hmoov seem ntawm cov khoom, nws yog qhov zoo dua rau kev nplua kom ceev cov hmoov nqus dej nce siab (Saib daim duab Ⅱ-8).Txawm li cas los xij, huab cua ntau dua tuaj yeem ua rau daim ntawv jamming, kho kom haum.

Yog tias tseem muaj cov hmoov seem ntawm cov khoom, tom qab ua kom ceev cov hmoov nqus mus rau pem hauv ntej, xyuas qhov siab ntawm sab saud thiab downward.Yog tias qhov sib txawv dav dhau, ua raws li cov kauj ruam dhau los los kho qhov siab.

Xyuas lub hnab plua plav uas tsis muaj hmoov los thaiv lub qhov cua.Raws li lub thickness ntawm hmoov, nws yog ib qhov tsim nyog los ntxuav lub hnab plua plav kom tsis txhob thaiv lub qhov cua.

Tshawb xyuas sab hauv qab ntawm lub tshuab, kom paub tseeb tias cov hmoov rov ua dua tshiab rau ntawm.

Kev cai ntawm tus nqi ntawm cov hmoov txhuam

- Kho cov hmoov co ceev tswj (Saib daim duab II-22).

2. Kho cov hmoov co co ceev tswj (Saib daim duab II-22) tseem tsis ncav cuag koj qhov kev thov.Yuav kho tus ntsia hlau rau sab laug ntawm lub tawb (Saib daim duab ).

Txheej txheem rau fais fab tuag

- hloov tawm lub regulator ntawm plua plav tais (saib daim duab II -17)

- Kaw lub regulator ntawm co (saib daim duab Ⅱ-22)

- kaw qhov kev hloov ntawm lub zog nqus mus rau sab saud (saib duab II-7)

- kaw qhov hloov ntawm lub hwj chim nqus qis qis (saib duab II-10)

- kaw qhov hloov ntawm kev xa khoom (saib duab II-4)

- hloov ntawm qhov hloov ntawm (saib duab II-21)

- Hloov ntawm tus tswj cov hmoov xa khoom (saib daim duab Ⅱ-15)

- kaw qhov hloov ntawm lub zog loj (saib duab II-2)

- Ntxuav lub vaj huam sib luag thiab npog nws nrog plua plav tsho

Tshuab tuaj

1. Tom qab kev khiav hauj lwm rau ib lub sij hawm, qhib lub baffle, thiab sau cov active qhov chaw nrog 20 # cav roj.Yog hais tias lub saw yog slack, siv lub elastic iav los kho.

2. Thaum hloov cov khoom siv raw xws li glitter thiab kub melting hmoov, siv cov cua compressed los ntxuav tag nrho cov khoom no kom tsis txhob muaj hmoov sib tov.

3. Raws li lub thickness ntawm hmoov, nws yog ib qho tsim nyog yuav tsum tau ntxuav lub hnab plua plav kom tsis txhob thaiv lub qhov cua.

Kev ua haujlwm khoob tshuab

Tig rau lub tshuab nce siab (Saib daim duab 3).Tig lub hloov mus rau sab saum toj ib nrab ntawm lub tshuab yuav sawv, txwv tsis pub tuaj.

Tig tus xa mus rau qhov tsis siv neeg (Saib daim duab II-4), thiab kaw tag nrho lwm cov kev hloov, ua kom cov yeeb yaj kiab ua ntej cua sov dhau los.

Kev daws teeb meem txhaum cai

1. Thov hloov tus tswv xeev ceev thaum nws tsis ua haujlwm.

2. Thov ua raws li cov lus qhia hauv Tshuab tuaj koom yog tias cov hmoov tsis nqus tag nrho li qub.Lossis koj tuaj yeem nce destaticizer los daws qhov teeb meem no.

3. Thov xyuas cov hmoov puas yog huv si thiab qhuav yog plua plav hauv qhov nyuaj.Yog hais tias cov hmoov ntub, thov insolating lawv nyob rau hauv lub hnub.

4.Yog cov hmoov rov ua dua lub raj thaiv, Thov xyuas hauv qab ntawm tus ncej tig cov txheej txheem residue pab.Lossis txheeb xyuas cov hmoov nqus hauv qab, xyuas kom nws khiav.

5.Tig qhov hloov mus rau sab saum toj ib nrab ntawm lub tshuab yuav sawv.

******************************************************** ******************************************************** ******************************************************** *********************

Manipulator